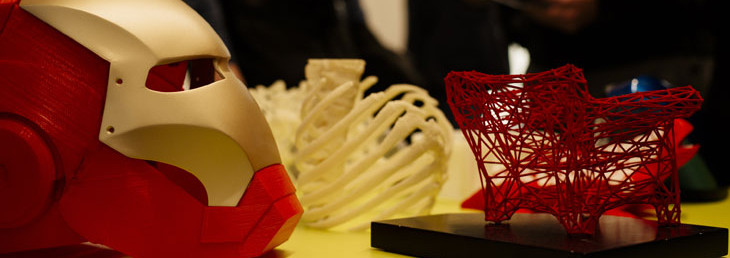

Co-Session#24 (I): Reinventing business through 3D technologies

3D technologies are already changing the way in which we come up with, design and even produce products and services. At Co-Society we wanted to dedicate Co-Session24# to explore the way in which this type of technology can be used to reinvent businesses.

It was a unique opportunity to get to know companies and organisations first-hand, be they start-ups or established companies, which have already introduced additive manufacturing in their processes, or that have even made 3D their core business.

One of the real success stories in this field is that of our hosts for this meeting: Fundació CIM, an organisation attached to the Universitat Politècnica de Catalunya, has grown into a cutting-edge technology centre in 3D printing technologies, combining its tasks of training, research and technological transference with a range of engineering and manufacturing services. From its facilities at Parc UPC in Castelldefels (Barcelona), Fundació CIM accompanies companies and society as a whole in an ongoing fourth industrial revolution which needs the right tools to make this possible. From the very beginning they have opted for open innovation and open hardware.

Companies that displayed and demonstrated their proposals were selected to cover different moments in the value chain and a wide range of sectors: retail, health, industry, entertainment…

ARRK: Industrial prototyping for businesses’ day-to-day work

With almost 70 years of history, ARRK has converted an essential part of its core business to production using 3D printing. “We are dedicated to taking products and designs off the screen and making them tangible.” A fine example of 3D printing for industrial application, ARRK has the technology to print pieces of a certain size down to the most minuscule, and in both high and low volume runs. Its engineering services include 3D printing of industrial prototypes which notably help reduce the time-to-market and prevent money from being lost from production errors or due to poorly focused projects.

Aitech: Trying on clothes without taking anything off

Not all 3D technology is necessarily related to printing. Aitech offered another approach to the 3D business with a presentation on its computerised vision technologies with applications within the retail sector. Based on the use of depth sensors similar to those used by the Kinnect console, Aitech has developed AiMirror, technology that can be used in virtual changing rooms or in interactive advertising campaigns using digital signage devices.

Exovite: 3D printing applied to health

This start-up is developing a clinical immobilisation system that replaces the traditional plaster. It is a totally personalised piece, printed in 3D in 30 seconds based on a scan of the patient’s limb and to which rehabilitation features are added through electrostimulation of the affected muscles. Exovite also showed other trends in 3D printing in the medical and health field, such as the democratisation being provided by giving access to prostheses of all kinds, the costs of which were previously prohibitive for most people when manufactured by traditional methods.

Blophome: Design your room in 3D with furniture from your favourite brand

Blophome has developed an interior design application that offers professionals in this sector a way to create three-dimensional environments without the need to know how to use the type of 3D software which up to now was too complex or technical. Users of this application can create three-dimensional environments to reproduce their interior design proposals or creations by simply selecting from over 200,000 objects created in 3D by manufacturers of furniture, doors and windows, bathrooms and all kinds of accessories, etc. and dragging them to a main screen.

Tumaker: Making 3D printing mainstream

These days, a 3D printer is still too difficult to use for most potential users. Tumaker wants to democratise 3D printing, offering “the easiest 3D printer in the world”, which is as easy to use as a microwave oven or MP3 player. A 3D printer is no more and no less than a device to reproduce a new category of contents: objects. With this approach, Tumaker seeks partnerships with companies interested in offering this type of content, linking it to their brands in the areas of hobbies and interests.

Mobile Media Content: Buy tickets, knowing what the view will be like from your seat

3D applied to the world of ticketing means that we can buy tickets for a sports match or cultural event, giving a faithful reproduction of the view we will get from that seat, according to its location within the stadium, auditorium or theatre. The technology developed by Mobile Media Content is also being used to analyse architectural projects in this type of venue, and to detect and correct potential errors related to poor visibility during matches and performances.

Ibarmia: Additive manufacturing also comes to heavy industry

Ibarmia is a machine tool manufacturer that decided to enter the world of additive manufacturing to help meet the growing demand for this type of production in sectors like the aerospace industry, power generation and the manufacture of moulds and dies. After analysing the different technologies available, the company decided upon laser metal deposition using powder (LMD-p) due to its ease of integration with the machinery already available, easier programming and more precise results.

HP: The present and near future of 3D technologies

3D printing has generated many myths. There is still a long way to go to until we can make a much vaunted industrial revolution based on this type of new technologies a reality. HP announces that it is willing to shorten this journey with Multi Jet Fusion, a revolutionary new technology that will be available on the market in 2016 and which promises to answer the current challenges of 3D, printing pieces at a rate 10 times faster than current printers with the same quality as those made using moulds.