No circular economy without a collaborative one

According to Ellen McArthur Foundation’s definition, a circular economy is “one that is restorative and regenerative by design, and which aims to keep products, components and materials at their highest utility and value at all times”.

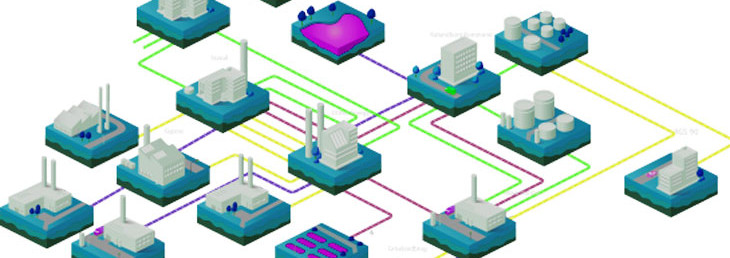

Much easier to declare than to make it real, we think collaboration and co-innovation will play a key role for cradle to cradle innovation to take place, as the real payoff of Circular Economy will come only possible when multiple players across the value chain come together to reconceive key manufacturing processes and flows of materials and products.

In an effort to keep control over valuable natural resources, some companies are thinking about new ways to reuse products and components. These ways are not easy to design and implement in a traditional linear economy where all links of the value chain are only used to establish buyer/seller relationships in which paying for the present cost is the only thing that matters, forgetting about other long term costs beyond that specific purchase and the individual players involved.

So, for companies the challenge of circular economy will mainly require a different way of thinking about the implicit contract established today with other players of the value chain such suppliers, distributors and even customers. Industry partnerships and consortia will be critical for developing challenging but necessary skills such reverse-logistics or reverse-network-management capabilities allowing, for instance, to design and optimize products for multiple cycles of disassembly and reuse. Tools and platforms for this to happen more easily will be necessary too. We have already describe in here the kind of tools required to drive circular collaboration and make it much likely.

Some best circular practices based in collaboration

Some examples already show how by joining forces different companies and organizations can begin to develop the projects and enabling mechanisms that could trigger a self-reinforcing virtuous cycle needed for circular economy implementation. Carmaker Renault, for instance, has been actively working to reduce waste for more than a decade. To support these efforts, the company formed joint ventures with a steel recycler and a waste-management company to bring end-of-use expertise into product design.

Renault also works with suppliers to identify “circular benefits” that distribute value across its supply chain. For example, the company helped its provider of cutting fluids to shift from a sales to a performance-based model. We have previously remarked in this blog as this kind of change in the business model, besides being highly recommended by Circular Economy’s evangelists, suppose a new value-capture modes that require going beyond traditional buyer/seller liaison. In this case, by changing the relationship’s nature and terms, Renault motivated its supplier to redesign the fluid and surrounding processes for greater efficiency, benefiting both companies. Renault’s total cost of ownership for cutting fluids fell by about 20 percent while the supplier became more profitable with a 90 percent reduction in the volume of waste discharge.

Dutch manufacturer of carpets Desso is another example of a company working with their supply partners to create ecosystems that support circular product designs. Early 2008, the company made the commitment to become 100% Cradle to Cradle by 2020. To achieve this goal, Desso operates a take-back program that collects end-of-use carpet tiles to recover their materials for further production or for sale to secondary materials suppliers. Italian producer of nylon yarn Aquafil became Desso main supplier for its capability for re-processing BCF (carpet yarn). Aquafil itself has established their own initiative, the Econyl Reclaiming Programme, as an essential tool that the company is putting in place to facilitate a reverse supply chain and ensure reliable materials inputs.

Some other best practices in partnerships for circular economy involve not just suppliers but new players such reverse-logistics providers. This is the case of global apparel retailer H&M and I:CO (name stands for I Collect), an organization specialized in providing the infrastructure needed to ensure that valuable raw materials from used textiles enter a closed loop production cycle and remain there. H&M launched an in-store collection program encouraging customers to bring in old clothes in exchange for discount vouchers on new H&M clothing (any pieces of clothing, from any brand and in any condition are accepted, not just H&M’s). I:Co is responsible for dispatching some items to the global secondhand-apparel market or being used as substitutes for virgin materials in other applications, from cleaning cloths to inputs for damping and insulation materials. Besides H&M, I:Co list of partners include Puma, The North Face or Levi’s among others.

Circular economy in the Renault Group

DESSO launches over 60% of its carpet tile range with Econyl, a yarn made from 100% recycled content

H&M first fashion company to launch global clothes collecting initiative